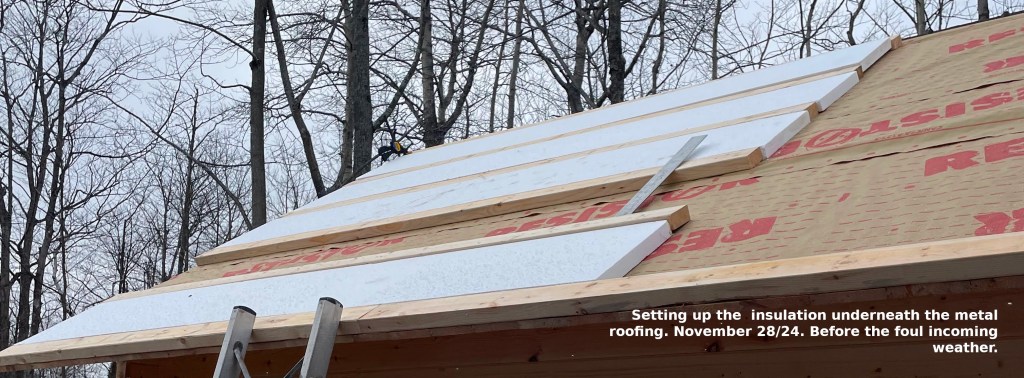

From a bunkie build point-of-view, we are making progress. Once that steel roof’s in place, I can begin drying that interior out with a propane-powered space heater. Then we can vacuum the exposed subfloor, apply Rockwool-type insulation, and add the floor panels. Bluntly, this bunkie kit has been a very costly build in T&M. It would have been much cheaper for us to have a unit built and delivered. Mind you, there would have been NO WAY to have the outbuilding located where it is. It’s tucked between the pre-existing e-shed and the main home.

There is a great deal of tweaking involved with the integrated power system (IPS). The generator has to be tied into the system and trigger itself at a Vminimum. And eventually go back into standby mode at a realistic Vmaximum. Otherwise that beast will suck on propane all day. That and the motor might prematurely fail. Snow sticks to solar panels and we have to figure out a safe way to clear the snow without resorting to laddres.

We are finding it tricky to have the French-designed electrical charging-control-inverter system, talk to the USA-made GENERAC, work with the Chinese PV panels and batteries, and keep the Austrian boiler running smoothly… without using too much Ontario wood pellets. And burn away limited, prehistoric fossil fuels.

Reason why there’s a heat-pump retrofitted into the e-shed? Lithium ion batteries and controllers-inverters don’t like extreme operating temperatures. If we get a cold snap (-15C or colder), I’ll be installing a tabletop block heater inside the insulated e-shed. Excessive heat during the summer should be removed without having to leave the door open!